Development of Sanitization Drone

Project Overview

Motivation

- The COVID-19 pandemic has significantly impacted health, economy, and daily life globally.

- Sanitizing large areas like halls, malls, parks, and streets is challenging, requiring significant manpower and time.

- Manual sanitization methods (e.g., hand pumps) are slow and tedious.

- Prolonged exposure to sanitizers can cause health risks such as skin irritation, respiratory issues, and liver damage.

- Drones offer an effective solution for large-scale sanitization, reducing human effort and exposure.

What Was Done

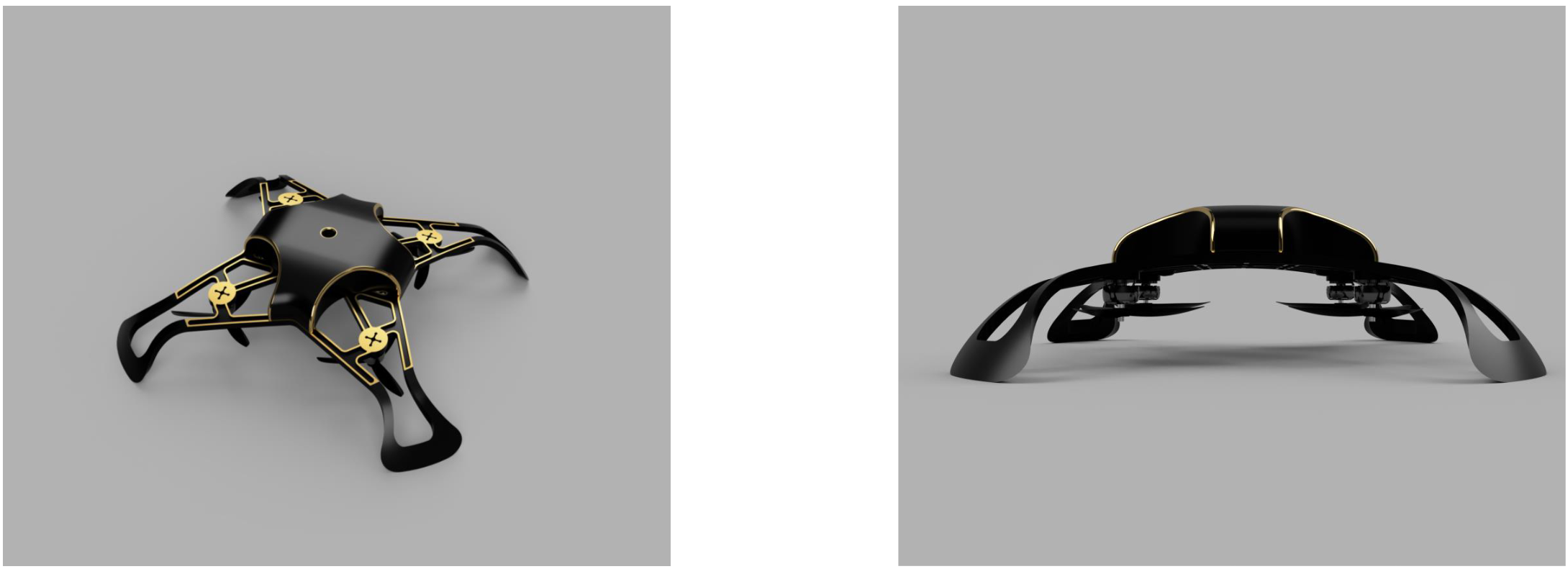

Drone Design

Designed and developed a 3D-printed quadcopter equipped with a sanitizer reservoir and spray system.

Component Selection

Conducted thrust calculations and selected components such as motors, batteries, and flight controllers.

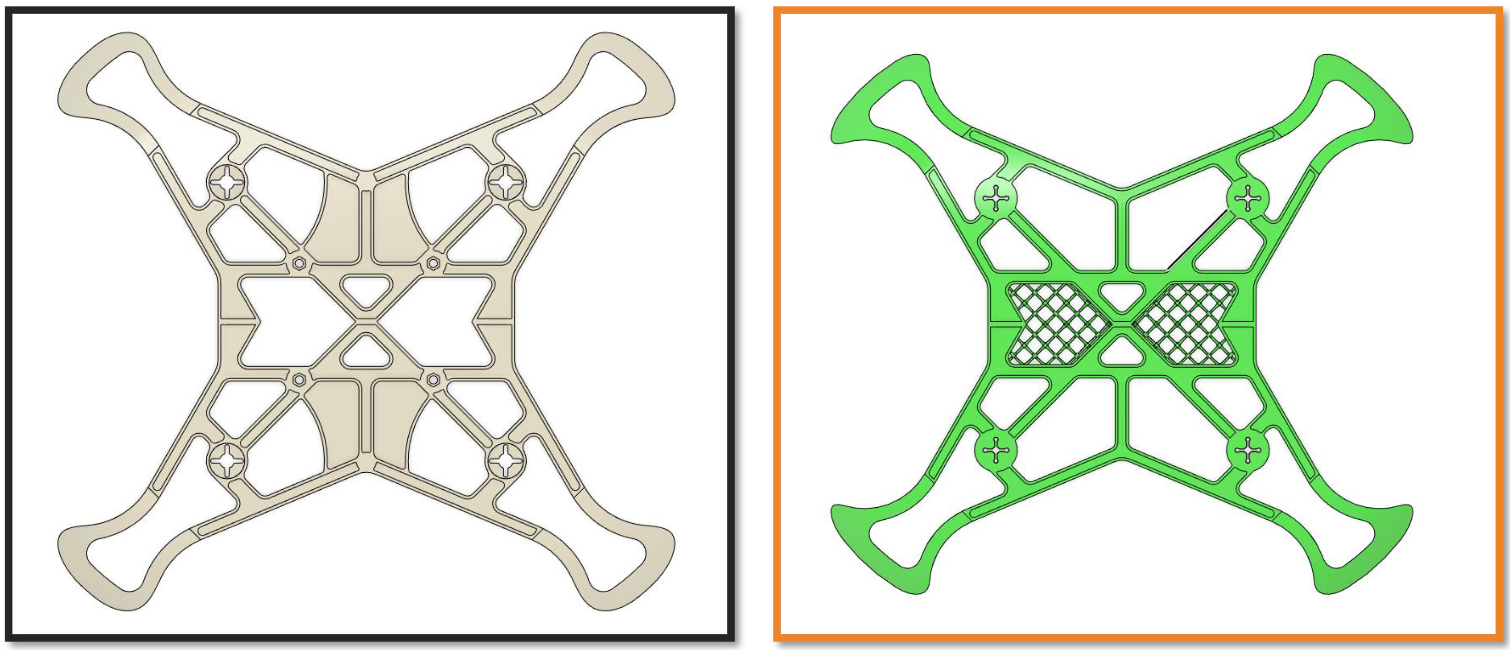

Design Iterations

Iterated the design to improve weight, strength, and aesthetics by scaling down the frame and replacing plates with grills.

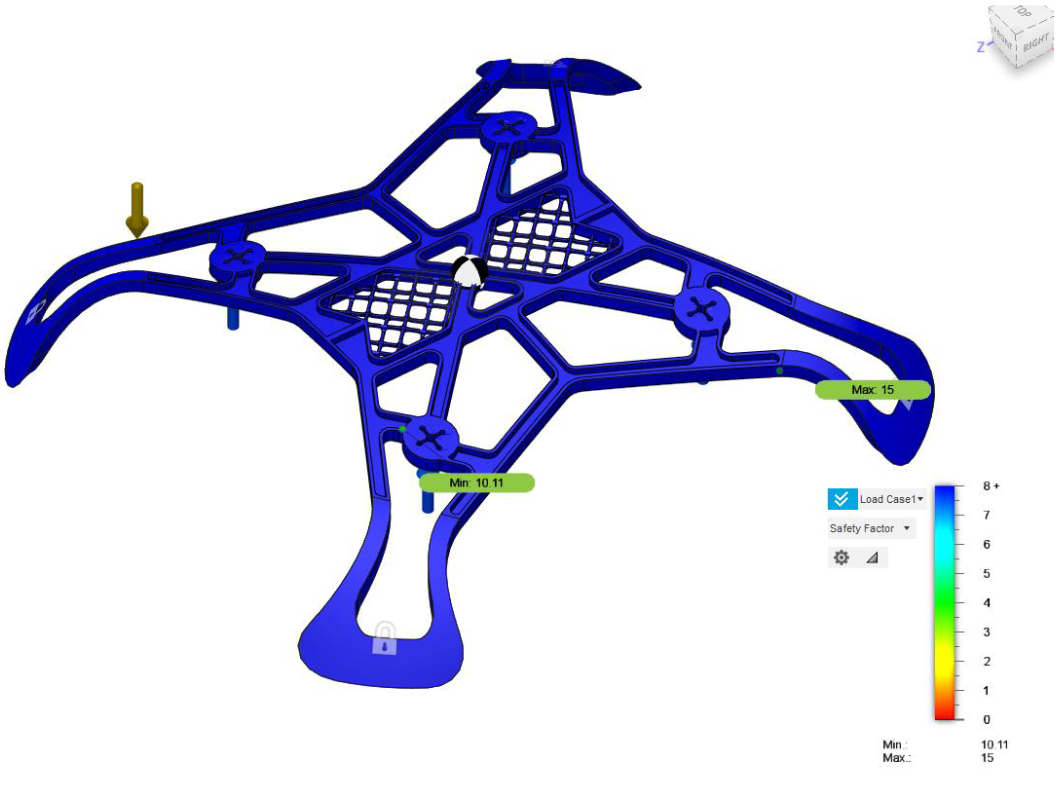

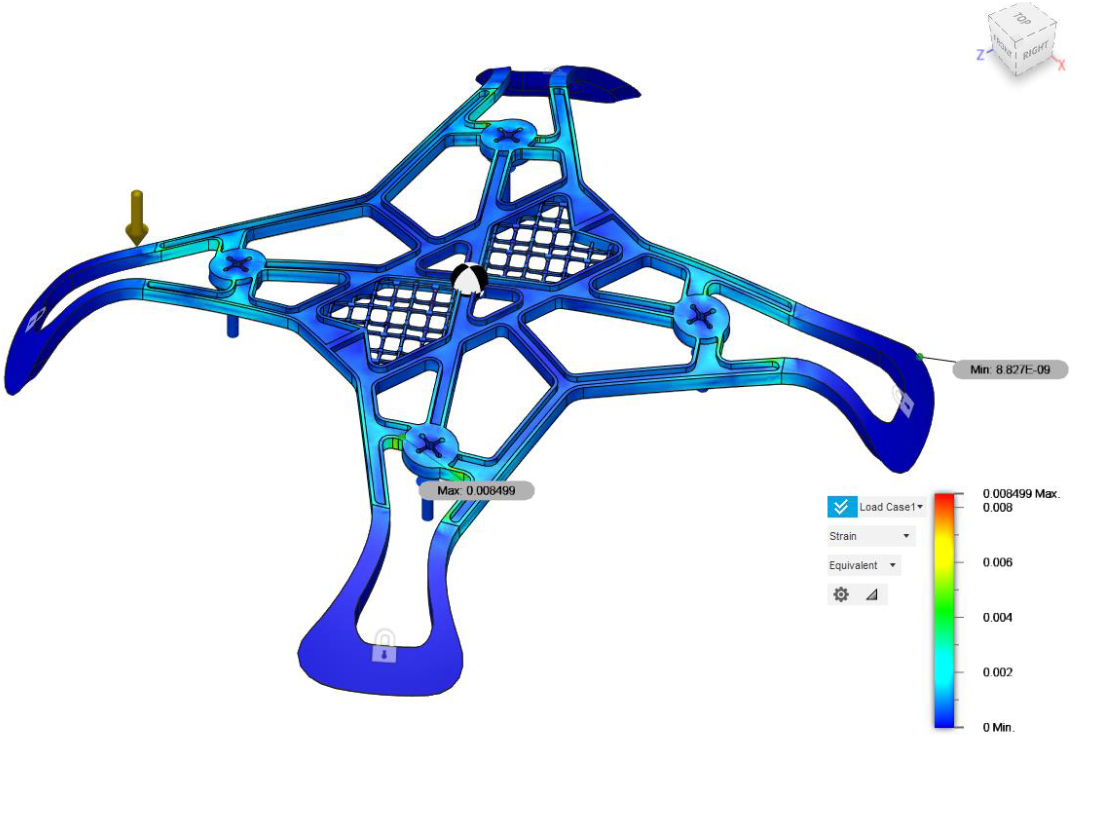

Analysis & Planning

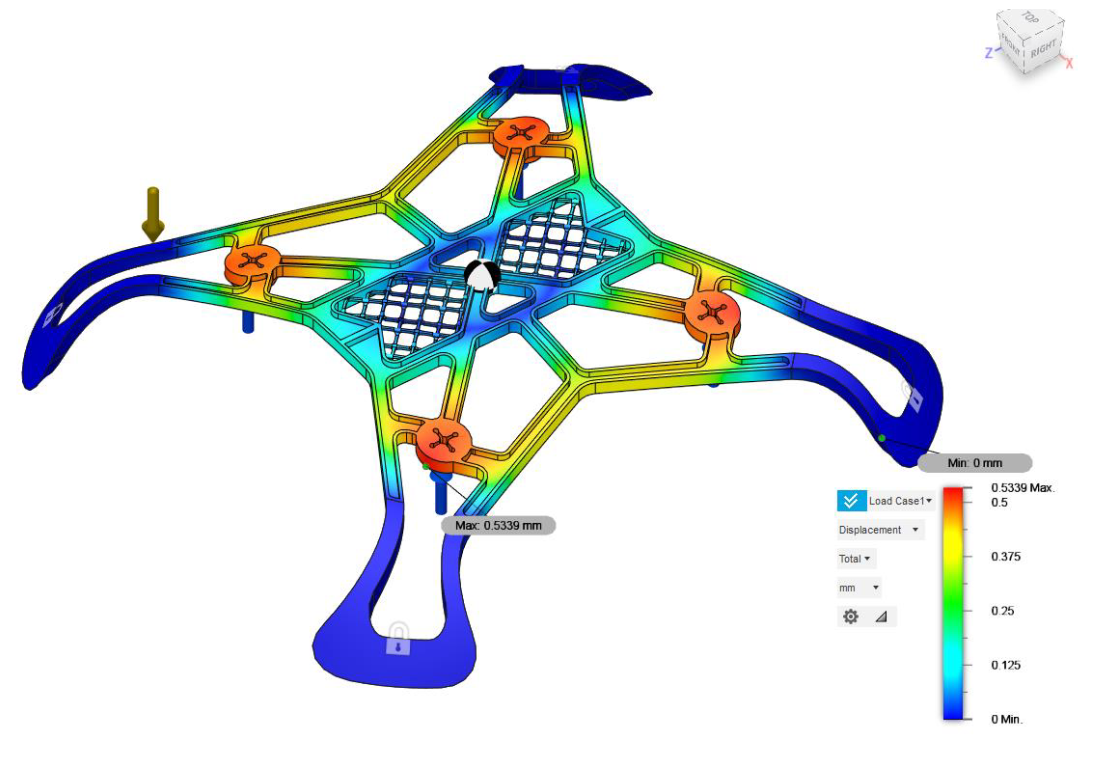

Conducted stress analysis and motion studies to ensure structural integrity and created a bill of materials for procurement.

What was Learned

Material Selection

The importance of material selection in drone design, balancing strength, weight, and cost.

Iterative Design

The iterative design process to optimize performance and resource utilization.

Integration Challenges

Practical challenges in integrating components like motors, batteries, and spray systems.

Simulation Value

The role of simulations (e.g., stress analysis) in validating design decisions.

What Was Achieved

- Functional Drone Design

- ~8.2 min Flight Time

- 1.7 kg Weight

- 4:1 Thrust Ratio